Mill Creek Generating Station Wikipedia

The Mill Creek Generating Station is a coalfired power plant owned and operated by Louisville Gas Electric in the Kosmosdale neighborhood of Louisville, is located 20 miles southwest of Downtown Louisville

WhatsApp)

WhatsApp)

The Mill Creek Generating Station is a coalfired power plant owned and operated by Louisville Gas Electric in the Kosmosdale neighborhood of Louisville, is located 20 miles southwest of Downtown Louisville

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

In addition, fossil plant requires either coal mills or oil pumps and draught plant,, FD and ID fans, PA fans, etc. Gascooled nuclear plant requires gas circulators running on main motors or pony motors at approximately 15% speed, whereas water reactors require reactor coolant pumps. Both nuclear types require various supporting ...

NewPage Luke Mill Power Plant. From SourceWatch. Jump to navigation Jump to search {{#badges: CoalSwarm}} Luke Mill Power Plant is a coalfired power station owned and operated by Verso Corporation in Luke, Maryland. The plant provides power to NewPage''s Luke pulp paper mill.

Mill Reject Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Coal Mill Reject ... Coal Mills in thermal power plant . bowl mill. Coal Mill Manual. Pulverizer Operation Performance and Testing. Protection and InterlockNTPC. Mill .

Coal Mill At Power Plant Improving Coal Pulverizer Performance And Reliability. BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. Figure 3 shows a cutaway of a RingRoll . After the sixmonth trial, the power plant installed one assembly on each of the 30 pulverizers in its facility.

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

How coalfired power plants work The Blogs at HowStuffWorks 4 Nov 2010 ... Coal, electricity, power plants, power grid, turbines, steam, cooling towers, generators. ...Here is the process that it describes: The plant ... The pulverizer is a ball mill – a rotating drum filled with balls that beat the coal. to dust.

{{#badges: CoalSwarm| Climate change}} Muskogee Mill Power Plant is a coalfired power station owned and operated by GeorgiaPacific Corporation which, in turn, is owned by Koch Industries in Muskogee, Okloma. The plant provides power to GeorgiaPacific''s Muskogee paper mill.

By Steve Coulombe, Product Manager for DSI mills at Sturtevant. Operators of coal fired power plants have a lot to worry about today: The price of coal relative to natural gas, stack emissions ...

Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system.

Bearing Solutions and Services for Thermal Power Plants. locations in coalfired power plants where bearings are typically used, such as in beater wheel mills, tube and bowl mills, and air preheaters.

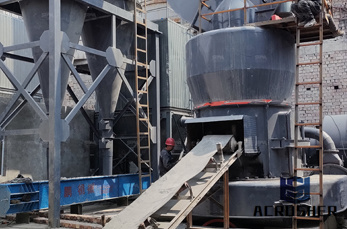

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

West Point Mill Coal Plant VA USA is located at King William County, VA, USA. Location coordinates are: Latitude=, Longitude= This infrastructure is of TYPE Coal Power Plant with a design capacity of 101 MWe. It has 5 unit(s). The first unit was commissioned in 1954 and the last in 1985. It is operated by SmurfitStone Corp.

Extending the Life of Coal Fired Plants through . money and jobs for plant facilities due to less closures while meeting the future energy demands of the community DSI with mill systems can be pretested by engineering. Chat Online

This industrial complex includes a 400 MW coalfired power plant consuming 900,000 tons/year of coal and a pulp and paper mill producing 500,000 tons/year of paper. The power plant uses coal and biomass, rice husk and wood bark, for fuel. The scope of mercury releases from power plants depends in general on the content of

Nigeria''''s coal deposits can sustain additional 4,300MW for 20 years ... May 10, 2017 ... Uwaifo said that Nigeria is in dire need of power supply that is stable and constant, which makes a case for a large coalfired power plant in the...

coal mill at power plant area | mining crusher equipment. This page gives you details about coal mill at power plant area from XSM Shanghai, Mill Department of Control Engineering In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant .

The ability of a coal power plant to accommodate significant changes in fuel quality is often limited by many constraints. When faced with a challenging goal to test torrefied biomass fuel at its ...

Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal rejects and fires. This is an example ...

Jan 09, 2016· Pulverizer or inother name Mill used for pulverized coal boiler of thermal power plant. The device pulverize coal to powder (pulverized coal) before blowing to burners of furnace.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standa...

causes less feeder hopper bridging and plugging problems. Coal feeders provide coal to the coal pulverizers (mills) where the coal is pulverized and dried. Dryer coal is easier to pulverize, and less mill power is needed to achieve the same coal fineness. Additionally, with less fuel moisture, more complete drying of coal can be achieved in the ...

A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection. ... The mill model is running in parallel with the power plant coal mill operation; the measured and predicted outputs are displayed on the computer screens in the power plant control room. ... The model is implemented online for mill condition ...

WhatsApp)

WhatsApp)