Cement Process Chemistry LinkedIn SlideShare

Nov 27, 2009· About Cement Cement Chemistry Cement is hydraulic material which develops strength when it reacts with water. It is inorganic material which consists of oxid. Slideshare uses cookies to .

WhatsApp)

WhatsApp)

Nov 27, 2009· About Cement Cement Chemistry Cement is hydraulic material which develops strength when it reacts with water. It is inorganic material which consists of oxid. Slideshare uses cookies to .

The chemical formula of cement is 2 O 2 O 3 Raw Material Required for Manufacturing of Cement The two important raw materials used for the preparation of cement are: 1. Limestone The chemical formula of limestone is CaCO 3 and it is used in the manufacture of cement .

Cement manufacturing process ... (2004) The History of Calcareous Cements in chemistry of cement and concrete, Elsevier ButterworthHeinemann. 15. Kosmatka, B. Kerkhoff, and .

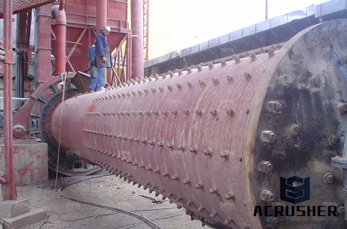

Each step of cement manufacturing, physical conditions and reactions occurred are explained here. Raw material transportation. Limestone is carried to the plant from mining place usually by a train. Some cement plants import clinker from other country or plant and add gypsum to produce cement. Mixing and Drying of limestone and clay

Established in 1994 and with a registered capital of million yuan, Jiangsu Pengfei Group Co., Ltd is a hitech enterprise specializing in undertaking overall contracting projects of designing, manufacturing.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Lea''s Chemistry of Cement and Concrete, Fifth Edition, examines the suitability and durability of different types of cements and concretes, their manufacturing techniques and the role that .

Today we are going to start here one very important topic chemistry of cement manufacturing. We will understand the various terminologies and engineering concepts used in cement technology with the help of this category. Further we will go for discussion of hydration of cement, properties of cement compounds, selection of the process ...

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and usually originates from is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker ...

Compound Composition of Clinker / Cement Four major compounds formed from the oxides under high temperature in the kiln Name (Oxide Notation) Shorthand Tricalcium silicate (3 2) – C3S Dicalcium silicate (2 2) – C2S Tricalcium aluminate (3 2O 3) – C3A Tetracalcium aluminoferrite (4 2O 3. Fe 2O 3) – C4AF

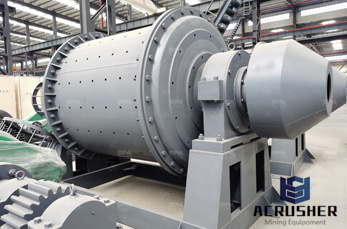

Dec 13, 2018· The cement manufacturing process consists of the following Steps: Grinding and mixing of the raw materials. Burning of the mixture at specified temperature for a correct duration. Grinding the consumed item called (clinker) along with gypsum.

Portland cement manufacturing (dry / wet) process (1). () Mixing and crushing of raw materials Dry process: In the dry process calcareous material such as lime stone (calcium carbonate) and argillaceous material such as clay are ground separately to fine powder in the absence of water and then are

Oct 10, 2015· Cement Chemistry Second edition by H. F. W. Taylor. This book is a classic of the Cement literature because the work of Taylor laid the foundations of our .

CemNet Training courses provide a thorough learning experience for cement industry personnel, with a wide range of features designed to accelerate full understanding of the complete manufacturing can learn 24hrs a day, 7 days a week over the course period at a time and pace that suits them. This cost effective training can lead to increased knowledge retention and a stronger ...

G. Habert, in Ecoefficient Construction and Building Materials, 2014. Introduction. Cement production has undergone tremendous developments since its beginnings some 2,000 years ago. While the use of cement .

Course Program. Module 1: An introduction to the Cement Manufacturing. This module addresses the fundamental principles of cement production. Module 2: Raw materials for cement manufacture. In the cement industry, the quarry is the extraction method for the production of raw materials in the cement manufacturing process.

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Aug 30, 2012· Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

Nov 27, 2009· About Cement Cement Chemistry Cement is hydraulic material which develops strength when it reacts with water. It is inorganic material which consists of oxid. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

High Industry Approval. Since its launch in early 2005, CemNet eLearning has been used by thousands of students worldwide. Such personel training has been taken up by multinationals including Lafarge, Holcim, Cemex and HeidelbergCement through to major companies such as Titan, Buzzi Unicem, Siam Cement, Yanbu Cement, Egyptian Cement, Vassilliko, JK.

Portland Cement . Cement: is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole. For constructional purposes, the meaning of the term "cement.

Cement Chemistry. Cement is chiefly of two kinds based on the way it is set and hardened: hydraulic cement, which hardens due to the addition of water, and nonhydraulic cement, which is hardened by carbonation with the carbon present in the air, so it cannot be used underwater.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Feb 21, 2011· Gives basic idea about cement, manufacturing process, composition, hardening and setting chemistry Slideshare uses cookies to improve functionality and performance, and to provide .

WhatsApp)

WhatsApp)