Cement Mill Maintenance FL

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, .

WhatsApp)

WhatsApp)

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, .

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, .

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, .

Modern Concrete Wall Grinding Machine To Increase Labor Productivity Construction Technology Thank for watching my video ! Subcribe me https://

cement ball mill productivity. Effect of clinker free lime and cement fineness on the cement physicochemical N H Mtarfi1* Z Rais1 M The first milling is done with a ball mill which is constituted a cylindrical chamber with horizontal axis and a capacity of 20kg It was used to prepare cement samples with a fineness primary The second milling was performed by using the HERZOG mill in order to ...

What Is The Production Of Cement Mill. We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity.

This can be applied to improve uptime of cement kilns and grinding mills. ... FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier .

The plant, for the Thang Long Cement Joint Stock Company, a joint venture of the Vietnamese companies Lilama and Geleximco, is in the province of Quang Ninh, near Halong Bay about 150 km northeast of Hanoi. As well as supplying the low voltage AC drives for the grinding mills.

grinding rolls for vertical mills in the cement industry The operating parameters of vertical mills are seldom altered once optimum productivity is established. But efficiency improvements – and therefore cost savings – can still be achieved with developments in metallurgy of the grinding .

Abstract: The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated. Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introduced.

EnergyEfficient Technologies in Cement Grinding . Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to higher energy consumption of conventional multicompartment ball milling circuits.

LE OF PRODUCTIVITY CEMENT GRINDING BALL MILLS. brief introduction to cement ball mill tube ball mill or cement tube mill is designed on the basis of cement ball mill has higher productivity and finer. Read More; ball mills in cement factory

grinding mills productivity petproducts. Improve Cement Ball Mill Productivity Grinding Mill . The Gulin product line consisting of more than 30 machines sets the standard for our industry We plan to .

Recommendations revealed in inspections help mills make the right changes to maximize their production and savings. Description Through this service, we conduct a basic grinding mill gear .

EnergyEfficient Technologies in Cement Grinding . Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding .

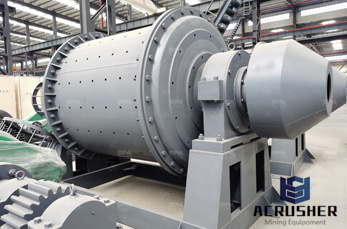

1. Chapters on safety around a ball mill 2. An overview of a ball mill 3. A ball mill''s components and the components'' functions, and on 4. Cement grinding systems with primary focus on closed circuit operation. This clip is on rotation, grinding, air flow and water injection in a ball mill.

Table Of Productivity Cement Grinding Ball Mills. clinker liquid phase ball mill productivity. ball mill for cement grinding Versatile system based on standard modules 2 The ball mill is designed for grinding of clinker . and mill productivity . Get Price vibrating .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, drives down costs, and reduces the environmental impact of operations. Present in more than 50 countries and headquartered in Copenhagen, Denmark ...

productivity increase of vertical roller mill for cement. Vertical Roller Mill,Verical Roller Mill Types. Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production.

This can be applied to improve uptime of cement kilns and grinding mills. ... FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, drives down costs, and reduces the environmental impact of operations

Denmark (trade named Cemax Mill). Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savings.

Oct 10, 2016· Should be noted, the productivity of ball mills depend on the drum diameter and ratio between the diameter and length of the drum. At the short ball mill grinding is a more rough and for grinding fineness a lot of material has to be returned from classifier to the mill, it leads to mill overload.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills .

WhatsApp)

WhatsApp)