Thu Process Of Washing Down Iron Ore

Thu Process Of Washing Down Iron Ore. Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

WhatsApp)

WhatsApp)

Thu Process Of Washing Down Iron Ore. Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

The primary use of iron ore is in the production of iron. Most of the iron produced is then used to make steel. Steel is used to make automobiles, locomotives, ships, beams used in buildings, furniture, paper clips, tools, reinforcing rods for concrete, bicycles, and thousands of other items. It is the mostused metal by both tonnage and purpose.

Mar 28, 2015· Washing. Washing is the simplest iron ore concentration process that takes advantage of the high specific gravity and comparatively coarse size of the iron bearing minerals to separate them from the finer, lighter, siliceous gangue which is predominantly quartz and clay minerals.

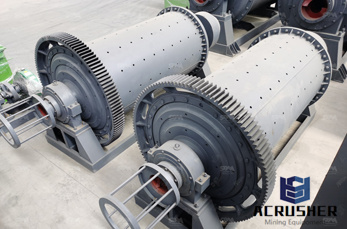

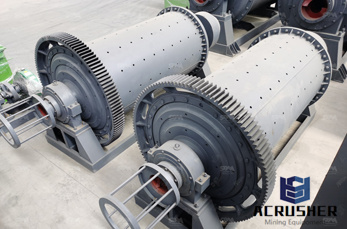

Iron Ore Line Crushing Plant Germany How A Iron Ore Crushing And Screening Plant Works,Shanghai XSM is a professional ore crusher equipment,How A Iron Ore Crushing And Screening Plant Works, mechanical beneficiation equipment, ore milling equipment mining process, the first belt conveyor, vibrating feeder, conveyor equipment ore

Further magnetic separation and milling produces even higher iron levels in the magnetite concentrate. The much sought after magnetite concentrate is primarily used for dense medium separation in coal washing and mineral preparation as well as a feed for iron ore. Magnetite is suited to coal washing due to its: High density; and

Iron Ore Beneficiation Solutions Across Project Lifecycle. Metallurgical Testing. To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operation.

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. Indeed, it has been argued that iron ore is "more integral to the global economy than any other commodity, except perhaps oil ".

Process Of Washing Down Iron Ore ssaconsultants . process of washing down iron ore process of washing down iron ore Get Price . How a Thickener Works . The Dorr washing thickener is of the multipletray type and is, in effect, a complete countercurrent decantation plant in a single compact unit. It is adapted to the needs of the small ...

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue.

Process description and technological phenomena of a column. The column is fed with ore pulp in its upper third portion and, at the lower section, air is injected at high velocities. This causes the pulp to flow down against a swarm of rising air bubbles. This countercurrent flow promotes the suspension of particles in the pulp.

M a ny iron ore producers are facing challenging times due to price uncertainty and the need to process crude material with increasing levels of impurities. Upgrading the ore through beneficiation processes, particularly washing (scrubbing), to earn more per shipped tonne can be the key to .

process of washing down iron ore. process of washing down iron ore beneficiation is a process which removes the gang particle like alumina silica basically it separates fe2o3 or fe3o4 from other impurities in the iron ore of water at various points down the spiral to assist washing of the concentrate ie

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive

installing the low grade iron ore beneficiation plant in this region. All these plant will be based on haematite ore as raw material. Based on this analysis, it is clear in India that the installation of beneficiation facilities exclusively for low grade hematitic iron ore beneficiation is .

Mar 14, 2014· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and ...

process of washing down iron ore process of washing down iron ore process of washing down iron ore. beneficiation is a process which removes the gang particle like alumina silica basically it separates fe2o3 or fe3o4 from other impurities in the iron ore of water at various points down the spiral to assist washing of the concentrate ie.

Optimization of an Iron Ore Washing Plant ... Closing down of iron ore mines due to environmental constraints spurred the captive iron ore washing plants to workon a custom plant mode and also recover the values from their slimy tails. This paper enumerates the difficulties faced by a captive iron ore fine washing plant [treating iron ore fines ...

From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation''s steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each...

Since the chemistry property of process water is entirely different from fresh water, there is a concern about the possible effects of the contained components on the efficiency of the flotation process . In iron ore flotation process, a large amount of NaOH is taken to adjust the pH.

Iron ore washing from CDE . Nov 1, 2011 ... Our iron ore washing plants have been developed to assist with the ... ore which leads to increased efficiencies in the steel production process...

The Direct Reduction of Iron Treatise on Process ... Mining and Beneficiation of Iron Ore. Like most metals, iron tends to concentrate in certain geological formations, leading to the existence of a number of ... Get Price; process of washing down iron ore vcareindia

Process Of Washing Down Iron Ore. energy and environmental profile of the u mining industry 41underground mining underground mines are established in areas with promising ore depositsron ore deposits may lie deep underground shaft must be dug from the .

Iron impurity was present as oxide and stained silica grains. The plant which was installed as a result of this test work is consistently making over a 95% weight recovery and a product with not over % Fe2O3 which at times goes as low as % Fe2O3. Silica Sand Washing Process .

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

WhatsApp)

WhatsApp)