(PDF) Hydrodynamics of Stirred Bioreactors

PDF | This review of the hydrodynamics of stirred bioreactors begins with an introduction to the agitation problems of particular concern in such systems. This is followed by a brief review of ...

WhatsApp)

WhatsApp)

PDF | This review of the hydrodynamics of stirred bioreactors begins with an introduction to the agitation problems of particular concern in such systems. This is followed by a brief review of ...

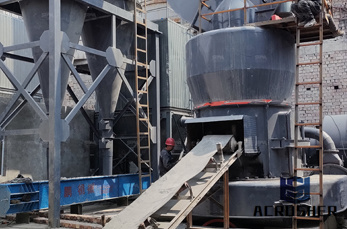

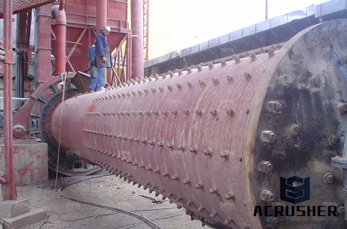

Grinding Mills: Ball Mill Rod Mill Design Parts 911 Metallurgist. Jul 10, 2016 ... Common types of grinding mills include Ball Mills and Rod Mills. This includes ... ton of product. Higher capacity per cubic foot of mill volume. ..... Whether of conical or starfish design, all .

A conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner. It is an alternative to the hammermill or other forms of grinding mills. As the name implies, the conical mill varies in diameter from where the feed enters to where the product exits.

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

ball conical ball mill operating principle Solutions ... operation of conical ball mill conical ball mill operating principle operation of conical ball mill Ball mill is the key equipment for materials smashing after the broken process is done the, Ball mill is the key equipment for materials smashing after the broken process is done the . ...

conical ball mill operating principle. dec 22 conical ball mill working principle it is a generally recognized fact that for economic reduction of any material it is desirable to . Get Price; working principle of conical ball mill . Conical Ball mill working principle: This machine is a skeleton pattern ball mill .

anfim doserless grinder anfim doserless grinder for sale . anfim grinder conical mills grinding mill equipment CoffeeGeek Anfim Doserless Grinder Carl S Lau s The only thing going for the Pavoni was that it is a conical grinder the chute and the mills The Anfim Get More Info 10 Best Coffee Grinders for Every Budget Updated for 2018 10 Best Coffee Grinders for Every Budget ...

conical ball mill for mica high popularity; conical ball mills australia; conical ball mill for zircon high speed; operating principle of the conical ball mill; conical ball mill for wolframite concentrator; conical ball mill for nickel high speed; conical ball mill energy saving jordan; conical ball mill .

News about Bachiller and our process equipment and pressure vessels for the chemical, petrochemical, pharmaceutical and food industries.

Lead Table Top Carbide Benchtop Tumbling Stirred Conical Batch Sand Quartz Coal Rock Ball Mill Pulverizer Experiment Size Set, Find Complete Details about Lead Table Top Carbide Benchtop Tumbling Stirred Conical Batch Sand Quartz Coal Rock Ball Mill Pulverizer Experiment Size Set,Lead Table Top Carbide Benchtop Tumbling Stirred Conical Batch Sand Quartz Coal Rock Ball Mill .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

This mill consisted of two conical mill stones, one hollow and fitted over the other, ..... and by partial vacuum, was much used in France, Holland, Germany, and Austria. ..... in 1881, and in 1892 it was granted a German patent on a ball roaster. Get Price

Jun 20, 2017· aluminium circles mill finish 1050 . New product Casting steel ore processing tumbling ball grinding mill . Tags: Customize Design Ball Mill . High Efficiency Performance Ball Mill . Fine Ball Milling Machine .. Lead Table Top Carbide Benchtop Tumbling Stirred Conical Batch Sand Quartz Coal Rock Ball Mill Pulveriser.

FermZilla Conical Fermenter – gal. / 27 L. The new and improved FermZilla, a 27 liter conical fermenter brought to you by the critical key minds and engineers behind the original Fermentasaurus Gen 1. Although the original Fermentasaurus was revolutionary at the time of its conception, there are always areas to improve upon.

The breakage power is supplied by the stirred mill. Since the stirred mill is a shearing machine, it delivers its power through shear, or more specifically, through the shear–volume power. Thus, the shear–volume power must be equal to the breakage power (71) 10 W i 1 P 801 F 80 Q = μ ω 2 V τ Eq.

conical stirred mill continuous conical ball mill talentgrowthcoin continuous conical ball mill continuous ball mill cone sand washing machineContinuous Conical Ball Mill Design jdpolymerscoin Ball mill ore crusher price Ball mill A ball mill is a type of grinder cone and the product is discharged through a continuous conical ...

The performance data of hydrocyclones in circuits containing a gravity induced mill (hereafter referred to as a stirred mill) were evaluated to understand their performance in the circuits and the ...

Jun 26, 2019· As of this posting, MoreBeer has this on sale for just as a preorder. These are expected to ship mid July. Order now to reserve yours Shipping is free with a qualifying 59 order to many US addresses. Price, promotions and availability can change quickly.. Please note that product prices and availability are subject to change.

Jun 16, 2017· This feature is not available right now. Please try again later.

The Blennerville Windmill is a m high, stone, reefing stage, windmill in Blennerville, Co. Kerry, mill has five floors, ground floor, intermediate floor, grinding floor, stone floor and cap floor. The mill was built in 1800 by order of Sir Rowland Blennerhassett and has two grinding couples with on the spindle a gear that is driven by the wheel with wooden combs.

High Energy Ball Milling How It Works . Spare Parts Request Form; High Energy Ball Milling. In discussions on high energy ball milling, the more generic term ball mills is often used in place of the terms stirred ball mills or Attritors, but the differences between the types of mills are quite distinct.

The following conclusions on the work of the Hardinge mill are based on data furnished to the writer by the Hardinge Conical Mill Co. in the form of the mesh cards hereto appended. Energy units (E. U.) and relative mechanical efficiencies (R. M. E.) are computed by the "volume method" of Stadler. Screen apertures used are the average apertures of testing screens of the meshes given.

An impact mill including a base portion on which is disposed a rotor rotatably mounted in a bearing housing, the rotor having an upwardly aligned cylindrical surface portion coaxial with the rotational axis. The impact mill is provided with a mill casing within which is located a conical track assembly which surrounds the rotor to form a conical grinding path.

Apr 09, 2015· Stirred media mills are usually constructed in the form of a cylindrical drum inside which there are a series of rods, arms or perforated discs which are rotated on a central shaft. The drum is loaded with grinding media, such as metal balls or glass sand. The media and the charge is ''stirred'' together and thus the grinding takes place.

WhatsApp)

WhatsApp)