GOLD Manufacture Process Discover Heavyweight ...

Jul 06, 2018· Watch this video if you WANT to KNOW GOLD Manufacture Process Discover Heavyweight Productions | Global Technology Detail Instructions are shown in the vid...

WhatsApp)

WhatsApp)

Jul 06, 2018· Watch this video if you WANT to KNOW GOLD Manufacture Process Discover Heavyweight Productions | Global Technology Detail Instructions are shown in the vid...

Jan 23, 2012· In modern times though, mining for gold is a much more intensive, yet sophisticated process. Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today. It''s largely a matter of technology and requires much expertise and elaborate equipment. Mining for gold today can essentially be broken down into 9 ...

Gold Key Processing''s experienced team of employees understand all aspects of custom compounding. Committed GoldKey Processing is a custom rubber compounding company. This is our only business. As such, we are focused to service the needs of our customers.

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well ...

manufacturing is to make or process a raw material into a finished product to manufacture is the act or process of producing something so there is no difference just that manufacturing is a verb ...

Jul 22, 2019· Mercury used in gold mining can be a problem that includes environmental risks and health risks for miners and others. Here is why you should be cautious. ... leaving behind the gold. This process does not result in gold that is pure, but it does eliminate the bulk of the impurities. ... Manufacturing Process of Copper.

The Miller process is rapid and simple, but it produces gold of only about percent purity. The Wohlwill process increases purity to about percent by electrolysis. In this process, a casting of impure gold is lowered into an electrolyte solution of hydrochloric acid and gold chloride.

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

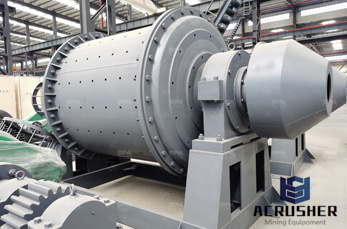

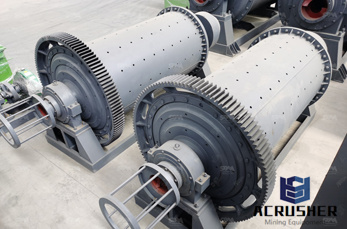

this mining operation. The process is currently unprofitable with a gold price around 300 per ounce. Process Description Unit 100 – Size Reduction of Ore The BFD of the overall process is shown in Figure 1. The PFD for Unit 100, shown in Figure 2, is designed to reduce tons/hr of gold ore from a feed range of 25" to 160 microns.

Gold Processing Plants. Star Trace offers turnkey solutions for gold processing plants. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold processing plant equipment. We specialize in gold processing plants, gold trommel plants and portable gold trommel plants.

At Jewelry Designs our artisans have passionately pursued the lost art of jewelry making since our company was founded in 1980. Designing jewelry from gold, platinum, diamonds and precious stones, our master jewelers create original jewelry in our shop. While still rooted in the spirit of old world craftsmen, the equipment and techniques we use ...

Uses of Gold in the United States: This pie chart shows how gold was used in the United States in 2017, not including gold bullion. The main uses were in jewelry (38%) and electronics (34%). The minting of official coins accounted for 22% of the gold used, and 6% was for other uses.

This process use electroplating and are important techniques for the economical and straightforward purification of nonferrous metals. Based on the ore property and test result, generally Gold Refining Machine For Sale generally contents: Chloride reduction process .

Jan 17, 2014· One of the major areas in which operators can not only become more efficient, but also cut energy and production costs, is in the processing of the gold. Importantly, unlike coal processing, gold ...

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Gold Peg makes industrial food processing equipment, specialising in direct steam injection continuous cooking technology. Gold Peg designs, manufactures, installs, and supports high performance food processing equipment, with the goal of improving the productivity of food manufacturing companies around the world.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

Each process relies on the initial grinding of the gold ore, and more than one process may be used on the same batch of gold ore. Mining 1 In lode or vein deposits, the gold is mixed with another mineral, often quartz, in a vein that has filled a split in the surrounding rocks. Gold is obtained from lode deposits by drilling, blasting, or ...

Dec 08, 2018· Extreme Amazing Casting Gold Melting Process And Casting Bullion At Work Hi!!.This Channel is About: Modern Machine in The World,Technology CNC Machine,Technology Solutions, Production ...

Aug 12, 2016· Given that each process requires a thorough comprehension of jewelry making, professional manufacturing entails working with a network of skilled artisans and craftsmen. Despite ancient origins, jewelry manufacturing processes such as lost wax and mold making are frequently used by jewelers today.

The gold can be removed from the carbon by using a strong solution of caustic soda and cyanide, a process known as elution. Gold is then plated out onto steel wool through electrowinning. Gold specific resins can also be used in place of activated carbon, or where selective separation of gold from copper or other dissolved metals is required.

Our proprietary process for manufacturing Gold (Au) evaporation materials minimizes spitting by reducing carbon and other contaminants resulting in improved yield and increased production uptime. VEM UltraPure Au elemental and composite evaporation materials are available in a variety of industry standard volumes and sizes.

WhatsApp)

WhatsApp)