iron ore wet milling process involved

ball mill for lime grinding . wet overflow grinding is a process whereby dry ball mills are used for wet grinding iron ore, sag and ball mill for the wet grinding of gold/copper ore in

WhatsApp)

WhatsApp)

ball mill for lime grinding . wet overflow grinding is a process whereby dry ball mills are used for wet grinding iron ore, sag and ball mill for the wet grinding of gold/copper ore in

After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding. With fine ore particles, it is more efficient to upgrade iron ore. Wet ball mill and fine ore crushers are used during this process. Spiral classification

iron ore wet milling process involved shravanospital. iron ore wet milling process involved Opportunities Mineral Processing For the processing of poorer ore qualities, wet processes have won through against dry processes, Dry grinding is only performed in HPGRs in fine grinding or ball mills and The rapid increase in iron .

Nanocrystalline IronOreBased Catalysts for FischerTropsch Synt ... Feb 1, 2016 ... Nanocrystalline iron ore particles were fabricated by a wetmilling process using an Ultra Apex Mill, after which they were used as raw materials...

iron ore wet milling process involved wet grinding for ironore pelletisation process and wet wet grinding process of iron ore and wet milling process of iron . Get Price. grinding of iron ore process . Ball mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ores, Process flow sheet for Pelletization using dry ...

When the ore is reduced to 3/4" or less, it moves out of the mill in a slurry solution. The mill discharge is screened at 1/4" on trommel screens attached to the mill. Ore smaller than 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron ...

The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB). However, Iron ores from different sources have their own peculiar mineralogical characteristics and require the specific beneficiation and metallurgical treatment to get the best product out of it.

The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry process whereas grinding is generally performed wet and hence is more energy ...

a mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting attrition between grinding balls and ore particles causes grinding of finer particles sag mills are characterized pebbles and ore particles may be used where product contamination by iron from steel balls must be avoided ... Iron Ore Wet Grinding ...

Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth''s crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Because iron is present in many areas, it is of relatively low value and thus a deposit must have a high percentage of metal to be considered ore grade.

Aug 26, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

During the wet processing, water is used to classify and purify the iron ore, removing impurities (such as silica) that affect the final product quality. Then, material must be exposed to moisture reduction processes in order to be stacked and transported to the clients.

wet vs dry iron ore mining – Grinding Mill China. dry and wet process iron ore Crusher Machinery For Sale HWC. dry and wet process iron ore wet vs dry iron ore mining 171 views. the is the professional mining equipments manufacturer in the world, located in china,india, along with other asian processing iron ore tenova . tenova is a .

Magnetic Separation Process, Iron Ore . Magnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator . Magnetic separator,Wet magnetic separator . The Magnetic Separator can separate raw materials with different magnetic rigidities.

Creating steel from low grade iron ore requires a long process of mining, crushing, Each primary mill contains several 4" steel balls that grind the ore as the mills turn. 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the to the traveling grate furnace for .

the ore is reduced to 3/4" or less, it moves out of the mill in a slurry solution. The mill discharge is screened at 1/4" on trommel screens attached to the mill. Ore smaller than 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron from the noniron material.

Iron Ore Separation Process,Preparation Equipment The separation of iron ore is iron ore beneficiation process, and according to the types of ore ... roller type magnetic separation machine;Fine ore commonly used wet type ... the rough concentrate to open the way into the rod mill for grinding.

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved. On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the ...

Ball mill for iron ore 280 t hr Ball Mill/ Ore Grinding Mill/ Wet Type Grinding Mill/ Dry Type Grinding MillSand ... Get Price. MTW Series Trapezium Mill Zenith. Trapezium Grinding Machines For sale, MTW Series Trapezium Mill From China Zenith. Get Price. ... iron ore crushing process iron ore jaw crusher vibrating feeder primary crushing ...

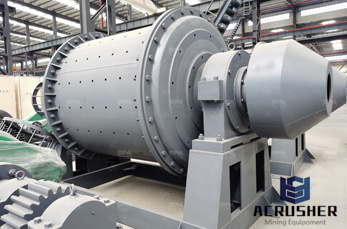

Ball Mill Suppliers Iron Ore Grinding Ball Mill Machine Overflow Type Wet Milling. Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine.

wet ball mill process in iron ore mills. wet ball mill process in iron ore mills; wet ball mill process in iron ore mills. Drum Mill / Rod Mill TM 300 XL RETSCH. The grinding process is performed either in dry or wet conditions. The drum mill can be operated either as a Ball or as a Rod Mill by using the corresponding. Live Chat

Wet Beneficiation Of Low Grade Iron Ores, Or Tailings Of .. Iron ore pelletisation, using vertical shaft kiln Pelletisation is the process of formation of green balls (916 mm) by rolling the iron ore powder with a small quantity of binder hardening the same by heat treatment in oxidizing conditions, up to temperatures of 1,2501,350°C.

iron ore wet milling process involved iron ore wet milling process involved Iron Wikipedia, the free encyclopedia Iron is a chemical element with the symbol Fe . Smelting Wikipedia. Process Smelting involves more than just melting the metal out of its, Most early processes in Europe and Africa involved smelting iron ore in a bloomery, . ...

Iron Ore Wet Process Ball Mill Gold ore ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grind able gold ore ball mill for mineral processing in africa get price how does iron ore wet processing plant workome crusher solution 06 how does iron ore wet processing plant work ...

WhatsApp)

WhatsApp)