Harvey Tool Speeds and Feeds Guide | General Machining ...

Calculate the Speeds and Feeds of Carbide End Mills, Diamond End Mills, and Plastic Cutting Carbide End Mills with these General Machining Guidelines

WhatsApp)

WhatsApp)

Calculate the Speeds and Feeds of Carbide End Mills, Diamond End Mills, and Plastic Cutting Carbide End Mills with these General Machining Guidelines

Ball Mill Machine For Aluminium. Ball mill is a kind of grinder that is widely used for grinding materials into a fine powder so as to be used in mineral dressing processesur ball mill is suitable for grinding lime mortarall mill that we offer operates on the simple principle of impact in which the size re more.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet ...

offers 5,637 aluminum oxide ball mill products. About 44% of these are ceramics, 19% are mine mill, and 1% are other fabrication services. A wide variety of aluminum oxide ball mill options are available to you, such as industrial ceramic, structure ceramic, and refractory.

Lab Scale Small Ball Mill Machine For Aluminium Powder, Find Complete Details about Lab Scale Small Ball Mill Machine For Aluminium Powder,Ball Mill Machine,Small Ball Mill,Lab Scale Small Ball Mill from Supplier or ManufacturerChangsha Yonglekang Equipment Co., Ltd.

offers 3,445 aluminum ball mill products. About 17% of these are mine mill, 2% are grinding equipment, and 1% are other fabrication services. A wide variety of aluminum ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

UltraPerformance End Mills Supermill LLC. Looking for maximum productivity while machining a variety of materials? Supermill can help. We manufacture a variety of ultraperformance, allpurpose, and highperformance end mills primarily made of carbide.

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ratio for ballmilling a new material? ... original powders were milled by ...

Mar 01, 2007· Choosing and applying the correct carbide end mill will result in substantial time savings for your shop. Three key things to remember are: Use an end mill specifically designed for aluminum machining. Use a machine with high speed and feed capabilities. .

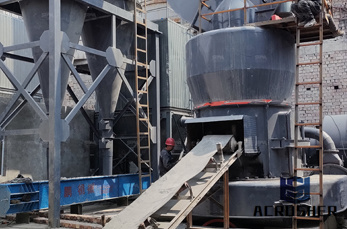

Ball mill is the key machine to grind the crushed materials. Ball mill machine is widely used to process cement, silicate product, building material, refractory material, fertilizer, ceramics and glass, ball mill, also called rod mill, can work in a dry way or a wet way.

Supply Aluminum Paste Plant Used Grinding Ball Mill Machine. We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity.

Ball Mill Aluminum Powder. Sanland Ball Mill Machine special feature for ball mills: Our Ball Mill Equipment adopts American Allis Chalmers techlology, are very welcomed and recognized by Noth America, South Africa and South America. Ball Mill For Grinding Features: Ball mill for grinding are composed of such major parts as feeding, discharging, revolving and driving parts (reduction gear ...

Noncentercutting End Mills are suitable for peripheral milling and finishing, but cannot be used to make plunge cuts. HSS and Cobalt End Mills will specify if they are center or noncenter cutting. Atlas Cutting Tools end mills offer a variety of coatings. Some end mills are uncoated, while others are coated with finishes to enhance performance.

A Ball mill or pebble mill is a milling machine is a milling machine that is equipped with hallow cylinder, containing balls so that it can be rotated along its longitudinal axis. This Ball mill is widely used for milling ores to manufacture of pharmaceutical...

offers 3,587 ball mill aluminum products. About 38% of these are milling cutter, 1% are machining, and 1% are rolling mill. A wide variety of ball mill aluminum options are available to you, such as broaching, drilling, and milling.

Jul 20, 2019· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Grizzly Industrial®, Inc. is a national retail and internet company providing a wide variety of highquality woodworking and metalworking machinery, power tools, hand tools and accessories. By selling directly to end users we provide the best quality products at the best price to professionals and hobbyists.

Aluminium dross cooling and ball mill machine. Aluminium dross cooling and processing system equipment main function: cool the hot dross generated from rotary furnace or dross processing machine through water spraying, break up, ball mill grind and crush, separate in different grades, so that it can get improving aluminium recovery rate purpose.

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

Mill

Fabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied. As foil thickness decreases from 60 to mm, mean size of powder milled for 30 h decreases from 107 to 17 mm. It is impossible to mill .

Dec 13, 2013· Yes, there are different compositions of aluminum. Some nearly impossible to mill. 6061 is best with woodworking tools. Length of the slot was inches. The ball end made the plunge cut much easier on the machine. The difference between end mills and spiral router bits is that end mills are available in many more collet sizes than router bits.

detection, etc., is usually produced by the dry ball milling of atomized aluminum powder. Wet ball milling is used mainly in the paste manufacturing industry for paints and inks, in which milling is performed in inorganic solvent [3,4]. A feasibility study for producing flake powder using aluminum foil scrap and the milling behavior of foil has

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

WhatsApp)

WhatsApp)