How Cement is Made | CEMEX Egypt

is a platform for academics to share research papers.

WhatsApp)

WhatsApp)

is a platform for academics to share research papers.

Cement manufacturing is an energyintensive process and a major portion of this energy comes from burning coal, especially in developing countries. Coal supply reduced globally during the historic period due to logistics issues and decline in investments in coal extraction, negatively affecting the cement manufacturing industry.

Egypt has increased cement production from 4 million tons in 1975 to 46 million tons in 2009, and now accounts for around % of global cement production. Dust emissions contribute about 6% of the PM 10 in Greater Cairo reaching as much as 30% in

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts for about 5% of total anthropogenic emissions (IFC, 2017). Cementbased structures constitute the largest surface area of all manmade structures (Odigure, 2009).

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone.

Jun 07, 2020· In a developing, highly populated country like Egypt, the construction construction material industry accounts for a large share of the Egyptian Economy, estimated to be % of the overall economy. The cement industry accounts for 1% of the Egyptian GDP, and almost 10% of the Egyptian manufacturing GDP.

ii Cement and Lime Manufacturing Industries At present, about 78% of Europe''s cement production is from dry process kilns, a further 16% of production is accounted for by semidry and semiwet process kilns, with the remainder of European production, about 6%, coming from wet process kilns. The wet process .

Subscribe to International Cement Review 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to News, Articles and HD Videos. £ 205 / US 315 / EUR 260

As the Operations and Technology Vice President of CEMEX Egypt and United Arab Emirates, Mr. Cabrera is accountable for a wide range of responsibilities which encompasses: Safety, cement production process, cement mills, preventive and predictive maintenance, projects innovation, quality assurance, quarries, raw mills and kilns as well sustainability including environmental affairs and ...

Here, local authorities often offer subsidies for waste processing, bringing added economic benefits to the cement plant operations. With cement production processes consuming such a large amount of energy, the opportunity is clear for cement plant operators to introduce alternative fuels coprocessing to their combustion and production processes.

2. Cement Manufacturing Process: The main component of cement is clinker, which is produced from raw materials, such as limestone and clay. [8]. Limestone supplies CaCO 3 for the cement production. Silica, alumina, and iron are considered to be other raw materials. The lime stone used for cement manufacturing contains 7590 % of CaCo 3

Regarding the history of cement in Egypt, Amin pointed out that Egypt was one of the first countries to establish cement manufacturing plants, noting that the first cement plant was founded in 1911 in Helwan governorate. The number of Cement plants in Egypt recorded 23 factories in 2017, he said.

THE CEMENT MANUFACTURING PROCESS 1. RAW GRINDING : The raw materials are very finely ground in order to produce the raw mix . 1. RAW GRINDING Raw grinding and burning 2. BURNING 2. BURNING : The raw mix is preheated before it goes into the kiln, which is heated by a flame that can be as hot as 2000 °C.

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Export development profits fell by % in June to about one billion pounds The profits of the Export Development Bank of Egypt decreased by % during the financial world ending on June 30, 2020,.

Cement grinding. As the last process, the cement grinding will consume a great deal of electricity. And in this process, special size granule cement will be obtained. (7). Cement Packaging. The cement can be transported in bulk or in bags. cement process. The manufacture of cement is a very carefully regulated process comprising the ...

kilns allowed cement manufacture to become a continuous rather than a batch process • Portland cement today, as in Aspdin''s time, is a predetermined and carefully measured chemical combination of calcium, silica, iron and aluminium, yielded by a complex manufacturing process, subject to rigorous control and involving a wide range of ...

Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water. 2 Dry process ___ grinding and mixing of the raw materials in their dry state. The process to be chosen, depend onthe nature of the used raw materials.

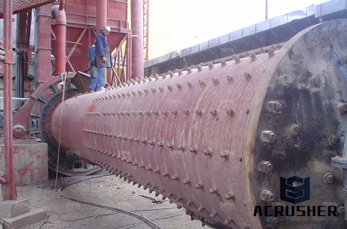

Burning : In this operation, the slurry is directly fed into a long inclined steel cylinder called Rotary kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones : In the wet process, the drying zone is comparatively larger than dry process. In is because the raw material in slurry form is directly fed into the kiln which has ...

Course Introduction and approach A new, instant access, online course, comprising of 14 lectures covering all aspects of raw material exploration, planning, extraction and preparation for use as cement clinker kiln feed.. The course is open to all in the cement industry and a fee will be charged for each student, with discounts offered to group bookings.

Compound Composition of Clinker / Cement Four major compounds formed from the oxides under high temperature in the kiln Name (Oxide Notation) Shorthand Tricalcium silicate (3 2) – C3S Dicalcium silicate (2 2) – C2S Tricalcium aluminate (3 2O 3) – C3A Tetracalcium aluminoferrite (4 2O 3. Fe 2O 3) – C4AF

Cement industry in Egypt A comprehensive overview of the construction industry in Egypt find real estate agencies and suppliers, as well as the latest industry news. ... Eco Associates is a contracting and engineering firm serving the manufacturing and service sectors. faculty of engineering. Industrial Construction Engineering (SIAC)

Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement. Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates. Cement plants can operate continuously ...

Chapter3 Cement Manufacturing Process 37 the negative air is vented out to the atmosphere. The collected fine powder is retrieved with the help of rapping mechanism and the same is fed to the process. Blending and Storage After filling the powdered materials from raw mill to a certain level in the ...

WhatsApp)

WhatsApp)