1. Grinding Grinding and Abrasive Machines

Grinding and Abrasive Machines Cylindrical grinder Work between centers Centerless ... sizes are for precision finish work, where a fine surface finish is required. The wheel ... a grinding operation: 8

WhatsApp)

WhatsApp)

Grinding and Abrasive Machines Cylindrical grinder Work between centers Centerless ... sizes are for precision finish work, where a fine surface finish is required. The wheel ... a grinding operation: 8

Nov 21, 2014· Belt grinding is a versatile process suitable for all kind of applications like finishing, deburring, and stock removal. 7. Bench grinder • Bench grinder, which usually has two wheels of different grain sizes for roughing and finishing operations and is secured to a workbench or floor stand.

The Grinding Machine Operator job function is to perform precision smoothing, sharpening, polishing, or grinding of metal objects. Duties: The Grinding Machine Operator must dress grinding wheels, according to specifications. The Grinding Machine Operator job function includes monitoring machine operations to determine whether adjustments are necessary; stop machines when problems occur. .

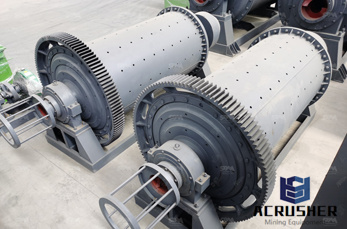

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high ...

Oct 11, 2017· Know the Applications and Uses of Cylindrical Grinding Machine ... It is primarily a finishing operation in which small quantities of metal are .

Sep 15, 2017· Using Grinding Versus EDM to Finish Form Tools. ... It included the company''s insert finishing departments that included a bank of Haas grinding machines and Agie wire EDM units. These two finishing operations begged the question: when should grinding be used and when should EDM be used as a finishing process? ...

The maximum size of a material that the grinder can machine is 18" long by 8" wide by 6" high. ... A relatively coarse grit size is selected for rapid stock removal without regard for finish as rough grinding; a fine grift should be used where a high finish is desired. ... The severity of the grinding operation also influences the choice ...

A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface quality. Grinding machine is a type of machine .

Nov 27, 2018· Surface Grinding Machine: Grinding Process, Specifications of Grinding wheelDetailed PDF: Grinding is the conventional finish machining Process used for producing a good surface finish on the components. The abrasive particles present on the surface of a grinding wheel will be acting as a single point cutting tools for removing the material from the workpiece.

Special types of grinders are grinding machines made for specific types of work and operations, for example: Tool and cutter grinders. These grinding machines are designed to sharpen milling cutters, reamers, taps and other machine tool cutters. The generalpurpose cutter grinder is the most popular and versatile toolgrinding machine.

Apr 15, 2002· Likewise, if turning is used on a grinder based machine, the turning operation is the LCD. Shops looking to invest in turn/grind multiprocessing machines should consider the predominant operation, be it turning or grinding, that will be used for the applications earmarked to be manufactured on the machines.

A deburring operation on a robotheld diecast part for an outboard motor housing, using a grinding wheel. Abrasive belts or flexible abrasive radialwheel brushes can also be used for such operations. Source: Courtesy of Acme Manufacturing Company and Manufacturing Engineering Magazine, Society of Manufacturing Engineers.

Nov 15, 2018· The centerless grinding can be categories into two type''s external centre less grinding and internal centreless grinding. We are familiar with the external grinding which is used for the finishing of the outer surface of the work pieces but the internal centre less grinding have some special applications such as grinding of holes for the shafts and other internal finishing operations.

Start with this definitive resource of key specifications and things to consider when choosing Honing, Lapping, and Superfinishing Machines. Products Services. ... Honing, Lapping, and Superfinishing Machines Information ... Machine includes a programmable logic controller (PLC) for programming and controlling a sequence of machine operations.

Dec 23, 2018· Grinding machine operates at high speed similarly other machine tools but the difference in the operation. The grinding machine used for finishing only after the machining done by some other machine tools. We can say that the function of the grinding machine comes into play after the machining of a work piece by turning or milling machines. The ...

Start studying ME2653 Exam 4. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... A _____ process using a _____tooth cutter to remove material with roughing and finishing operations performed in _____ of the cutter. ... The first grinding machines were made by Brown and Sharpe in the 1860s for the grinding of ...

Dec 08, 2016· A downside of centerless grinding is you can''t have as many multiple axes operating on the workpieces. However, there are many parts where the process addresses the limitations of machining in terms of dimensions, materials, and surface finishes. That''s why we like to say that where machining ends, the centerless grinding process begins.

Oct 19, 2012· Article on grinding machine, types and uses of a grinding machine, manual surface grinder, manual surface grinding machine including hydraulic surface grinding machine, cylindrical grinder, cylindrical grinder machine, centerless grinding, centerless grinding machine for automobile, electronic, electrical and engineering industries by leading distributors of machine tools, Bhavya Machine .

Nov 08, 2005· Milling On A Grinding Machine. A grinding machine is not a machining center, but it can sometimes take on milling and drilling (or even turning) to make the overall process more efficient. ... Grinding, of course, is typically thought of as a finishing operation. Milling is more about removing a .

May 08, 2018· The grinding machine isalso called as a grinder. The grinding machines are used to precisely finish and shape the given material with high surface quality and low surface roughness. It is basically a finishing operation which removes relatively small amounts of metal to produce products with high accuracy. But certain grinding applications also ...

Grinding Machine Definition: A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.. It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.. Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.

– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket contour ...

Grinding Roughs Out a New Niche Tyrolit Advocates a Patented Grinding Process for Rough and Finish Machining of Aerospace Parts. In the past, grinding has been a process that was primarily relegated to machining for final dimension accuracy and surface finish.

Surface grinding is the most common of the grinding operations. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces.

WhatsApp)

WhatsApp)