Mineral Processing SlideShare

Apr 01, 2014· We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime.

WhatsApp)

WhatsApp)

Apr 01, 2014· We use your LinkedIn profile and activity data to personalize ads and to show you more relevant ads. You can change your ad preferences anytime.

Mineral Processing Plant Design, Practice, and Control Proceedings . Practical and Theoretical Difficulties When Sampling Gold . USIM PAC 3: Design and Optimization of Mineral Processing Plants from Crushing to Refining Specification and Purchase of Equipment for Mineral Processing Plants.

Sep 01, 2017· Description: This book, consisting of 138 papers, covers all aspects of mineral processing plant design and will be valuable to engineers, consultants, suppliers, .

At most metallic mineral processing plants, each process operation requires several types of equipment. A single crushing operation likely includes a hopper or ore dump, screen(s), crusher, surge bin, apron feeder, and conveyor belt transfer points. Emissions from these various pieces of equipment are often ducted to a single control device.

Mineral Processing Plant Design, Practice, and Control (2 Volume Set) [Andrew L. Mular, Derek J. Barratt, Doug N. Halbe] on *FREE* shipping on qualifying offers. This 2 volume set is an uptodate reference based on 138 proceedings papers from the October 2002

Sulphide Gold . Gekko. When properly characterised, sulphide complex gold ores can be efficiently processed using a Gekko flowsheet design. . efficiently liberate gold from the host mineral of the particle will determine the process to use for optimal gold recovery. . ores include the Python plant and the Gravity Flotation Intensive Leach (GFIL).

Overview of Mineral Processing Methods. ... route can thus be identified mainly to recover iron that can be used as an alternative feed material for steelmaking plants particularly to replace ...

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

If the latter is the normal procedure it may be due to the mineral not being liberated from the waste well enough to be floated cleanly away from the native rock. When liberation problems are part of the ore''s characteristics the designers of the concentrator plant will include a REGRIND MILL in the Basic Flotation Circuit Design of its flow ...

Sep 13, 2013· For more mineral processing videos visit my YouTube Channel: Description: The thickener is used to increase the ...

These separators are commonly used for separating mineral sands, an example of one of these mineral processing plants is the CRL processing plant at Pinkenba in Brisbane Queensland. In this plant, zircon, rutile and ilmenite are separated from the silica gangue. In this plant, the separation is performed in a number of stages with roughers ...

currently operating plant. Process overview and description The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and ... The process design of gold leaching and carboninpulp circuits

the primary or basic industries of early civilization. Little has changed in the ... gold rushes that led to the settlement of California,Alaska,South Africa, ... assigned to metallurgy,although there is often some overlap in the mineral processing area with mining engineering. 4 INTRODUCTION TO MINING.

Welltech International Mining Equipment Co.,Ltd. is a large benefication service company specialized in designing, manufacturing, installing and debugging of benefication equipment as well as providing flow sheet design and plant design.

Characterization of gold minerals and carriers in composite ore sample can be used to diagnose and predict metallurgical response, identify potential problems, and help in the design of a more robust metallurgical test work program. ... This chapter provides an overview of some of the key drivers for gold process plant design on an area basis ...

Mar 15, 2018· The investment made in a gold processing plants, silver processing plants, as well as plants for recovery of other precious metals and rare earth minerals is .

mineral concentration process that is used to recover a vast array of different minerals containing valuable commodities such as copper, lead, zinc, nickel, molybdenum, tungsten, silver, gold, phosphate and potash. In the flotation process, ore is ground to a size sufficient to adequately liberate desired minerals from waste

Outlines the theory and practice in the design of flow sheets and operation of an integrated mineral processing plant; Introduces the basic magnetism, electrostatic, conductivity, and dielectrophoresis properties of minerals and related separation techniques

The Basic Technology Mineral Processing Ores Gold, Silver, Copper And Basic Techniques The Mining And Mineral Science Technology ... Gold processing in the Batu Hijau mine, through several process stages. Ranging from drilling and blasting rock mineral, up to hauling rock material into the processing plant area ... The tailings from the ...

Gold Processing Plants ... testing services for the delivery of the Mt/y gold mine processing plant and associated infrastructure, including a 650 person accommodation facility, mine vehicle workshops and light industrial areas. ... design, commissioning and operation of mineral processing plants. VIEW PROFILE . Greg Lane.

Mineral Processing Plant Design Construction Example. Previous Next ... Mineral Processing Plant Location. ... Ore minerals are galena, tetredrite, chalcopyrite, pyrite, and sphalerite. Gold and silver values occur partially free, and the balance associated with .

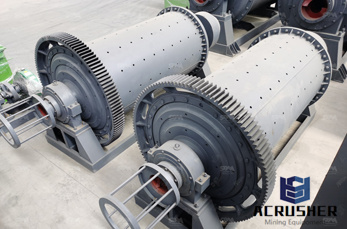

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Sepro Mineral Systems Corp. is a multinational corporation founded in 1987 and headquartered in British Columbia, Canada. The outcome of the acquisition of Sepro Mineral Processing International by Falcon Concentrators in 2008, the companies'' key focus is the production of mineral processing equipment for the mining and aggregate industries.

the primary or basic industries of early civilization. Little has changed in the ... gold rushes that led to the settlement of California,Alaska,South Africa, ... assigned to metallurgy,although there is often some overlap in the mineral processing area with mining engineering. 4 INTRODUCTION TO MINING.

WhatsApp)

WhatsApp)