rolling process in hindi YouTube

Mar 23, 2018· Types of rolling mill used in rolling Duration: 13:00. Mechanical lectures in hindi 6,707 views. 13:00. ... Rolling mill machine concept by Basic Engineering Duration: ...

WhatsApp)

WhatsApp)

Mar 23, 2018· Types of rolling mill used in rolling Duration: 13:00. Mechanical lectures in hindi 6,707 views. 13:00. ... Rolling mill machine concept by Basic Engineering Duration: ...

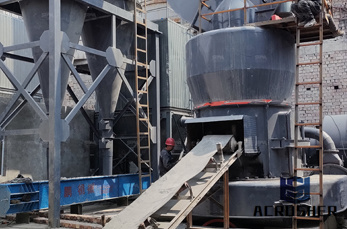

In a metal rolling process, rolls, stands, bearings, housing, motors, and other mechanical equipment are all a necessary part of the manufacturing operation. The place where all the equipment for metal rolling manufacture is set up is called a rolling mill. Rolling mills often vary in the type.

ALUMINIUM ROLLING MILLS TECHNOLOGY, MECHANICAL ENGINEERING, AUTOMATION AND ELECTRICAL ENGINEERING FROM A SINGLE SOURCE – CUSTOMIZED ... Strip caster Combined strip caster and hotrolling mill Hotstrip rolling mill Tandem coldrolling mill Coldrolling mill Slitting line ... This mill type can be used for foil roughing applications.

Chain drives are employed for the wide range of power transmission applications, like in bicycles, motorcycles, rolling mills, agricultural machinery, machine tools, conveyors, coal cutters, etc.. A chain drive consists of a chain and two wheels, called sprockets are toothed wheels over which an endless chain is fitted.

Oblique cutting occurs when the major edge of the cutting tool is presented to the work piece at an angle which is not perpendicular to the direction of the feed motion, its diagram show that chips removal are the continuous type.

Equipment design and supply of rolling mill machinery including millstands, shears, cooling beds and auxiliary mill equipment. Pass design services, physical pass design simulation, operations consulting and specialized rolling courses. Civil and mechanical services discipline engineering including baghouse design.

A four high rolling mill is used for the hot rolling of armor and other plates as well as cold rolling of plates, sheets and strips. 4: Tandem rolling mills: It is a set of .

Mill Machining, Milling Process, Horizontal Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

May 26, 2010· Sorry for the interruption. We have been receiving a large volume of requests from your network. To continue with your YouTube experience, please fill out the form below.

High speed steel (Hss) material is widely used to make the broach. It is also raised carbide of disposable inserts or sometime used for cutting edges then machining cost iron parts, which requires close tolerance. Carbide tools are also used to an advantage on steel cutting. A broach .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Sheet Rolling Mills Major Six Types Of Rolling Mills ; Explosive Welding – Principle, Working, Application ; Types of production systems ; 15 Mechanical Properties Of Engineering Material ; Introduction to IronCarbon Equilibrium Diagram | Structures in FeC Diagram ; Introduction Lathe MachineTypes Of Lathe Machine,Lathe Machine parts

A Case Study on Total Productive Maintenance in Rolling Mill Chetan S Sethia1, Prof. P. N. Shende2, Swapnil S Dange3 1Student, (PRODUCTION), 2Assistant professor, 3Student, (PRODUCTION) Department of Mechanical Engineering, Yeshwantrao Chavan College of Engineering, Nagpur, India.

88 Rolling Mill Engineer jobs available on Apply to Metallurgical Engineer, Equipment Engineer, Process Engineer and more!

Mar 12, 2017· There are specialty rolling mills that can roll right on down to foil thickesses, say " or even less. A mill that is designated as a 20" mill is typically able to handle material up to 20" in width. I worked for a while on a 120" cold mill, a mill that could roll up to 120" in width. For more information, look up cold rolling and hot rolling.

The Mechanical Machining and Construction Division at Galbiati Group is the ideal partner qualified for custom construction of mid and largesized components that require high quality standards.. Experience, teamed with our continuously updated production technology, has led to longterm relationships with leading companies in the steel, energy, and general engineering industries.

Mechanical engineering general discussion Forum; Rolling mill stands Quick release coupling corrosion. thread. Forum: ... I am working in a steel rolling mill. Our quick release couplings being used for air oil distributor on rolling stands are made of stainless steel. ... Engineering is not the science behind building. It is the ...

The mill provides forging action as well as rolling action at the same time. There will be two high mill at the beginning feeding the work piece to the planetary mill. At the out let end there will be another set of two high mill to take the out coming work. This arrangement provides roll tension at .

TYPES OF PRESSES There are over 300,000 presses in use in the United States and many more worldwide. Mechanical presses fall into two predominant press types: gap frame and straight side types. The frame types used in mechanical presses are similar to those used in many hydraulic presses. Here, we will limit our discussion to mechanical presses.

A tandem mill is a special type of modern rolling mill where rolling is done in one pass. In a traditional rolling mill rolling is done in several passes, but in tandem mill there are several stands (>=2 stands) and reductions take place successively. The number of stands ranges from 2 to 18.

High speed steel (Hss) material is widely used to make the broach. It is also raised carbide of disposable inserts or sometime used for cutting edges then machining cost iron parts, which requires close tolerance. Carbide tools are also used to an advantage on steel cutting. A .

The following is a list of Historic Mechanical Engineering Landmarks as designated by the American Society of Mechanical Engineers since it began the program in 1971. The designation is granted to existing artifacts or systems representing significant mechanical engineering technology.

Jan 14, 2013· RING A specialized type of hot rolling that increases the diameter of a ringThe resulting grain structure is circumferential, which gives better mechanical properties 17. CONTINOUS CASTING AND HOT ROLLING• Metal is melted, cast and hot rolled continuously through a series of rolling mills within the same process.

215 Paper Mill Mechanical Engineer jobs available on Apply to Mechanical Engineer, Process Engineer, Reliability Engineer and more!

WhatsApp)

WhatsApp)