Crushing And Grinding Of Limestone And Clay In Raw Mill ...

crushing and grinding of limestone and clay in raw mill ... Limestone Grinding Plant in Belgium. As the finished product is for a paper making company, our buyer from .

WhatsApp)

WhatsApp)

crushing and grinding of limestone and clay in raw mill ... Limestone Grinding Plant in Belgium. As the finished product is for a paper making company, our buyer from .

fly ash mix with clay make cement. In fly ash mix also the fly ash, which is burnt clay particles (oxides of clay) obtained from burning coal, which contains clay from the mines. When hydrated lime powder, gypsum are mixed and ground in a pan, the mixture gives a slow setting pozzalona cement.

Aug 29, 2018· History contains many references to ancient concrete, including in the writings of the famous Roman scholar Pliny the Elder, who lived in the 1st century and died in the eruption of Mt ...

Jun 19, 2016· Hi all, Here is how I lined my Coal Forge with Clay, Mortar and fireplace Ash. I created this video with the YouTube Video Editor (

What is the proportion of cement constituents (that is lizenithne and clay) that . of gypsum into a powder to make ''Ordinary Portland Cement'', the most in the Cement Industry Hardcover – .

Description of cement production technology Akmenės Cementas. If a raw mix is prepared as dry powder dry technology is being used. ... received from quarry and modified to wet suspension clay slurry in a clay wash mills. ... uses 35 % of all electricity and 90 .

Bedeschi, and Logmarin Advisors together make up a unique ... Focused on handling difficult materials as sticky coal and clay or dry mining and ... a full range of bulk handling solutions and a complete line of crushing equipment. Get Price

Lizenithne main ingredient used in cement manufacture; Engineer onsite ... of raw materials, such as lizenithne, clay, sand, mill scale/iron ore, and bauxite. More details » Get Price. Social Studies M3 Bauxite Other Minerals SlideShare. ... Add.: South Jinqiao Area,Pudong New Area, Shanghai, China.

Lizenithne crushing Cement manufacturing process Priya Cement. LT Hazemag, a Germanmade impact crusher, is used to crush 1200mm lizenithne boulders into 70mm lizenithne pieces.

Forecasting Coal Production Until 2100 Sciencedirect. World coal urr value has been estimated at between 700 and 1243 gt of model projects that worldwide coal production will peak between 2010 and 2048 on a tonnage basis, and between 2011 and 2047 on an energy notion that coal is widely abundant therefore appears to be unjustified.

The method was to grind natural chalk to a fine powder, then add water, clay as ... when manufacturers began to fashion chalkboards from synthetic materials ... To make chalk, lizenithne is first quarried, generally by an open pit quarry method. Read More

Jul 08, 2014· This research set out to improve the engineering quality of clay using waste materials and a secret binder ingredient.. Clay is a natural material composed primarily of finegrain minerals. It ...

why ball mill is useful; why checking axial sample in cement grinding mill; why coal mill motor have low power factor; why is south africa mining industry competitive crusher for sale; why in mill grinding roller temperature will be high; after ball mill why we use hydrocyclone; why impact crusher run limestone is used; impact crusher why mobil ...

The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating lizenithne and added sand to make mortar, with... Read More. Manufacturing Process About Cement Cement: ... The raw materials required to manufacture cement are lizenithne and clay. Rocks extracted ... Quarry being mined: Cairo cement plant in ...

working principles of lizenithne crusher animation of how lizenithne crusher works . working principles of lizenithne crusher 3D animation of gas Primary crusher is the most widely used lizenithne crusher works as fusion to . Now understand; More Info principle crushing machine stone crusher india.

production of portland cement supplementary cementitious material, when used in conjunction with portland cement, contributes ... clay and shale, and volcanic ash. SCM''s that are hydraulic in behavior ... it is possible to make concrete with moderate strength using the fly ash as the sole cementing material (Cross 2005). ...

Fillers add no energy value. It only adds ash content. Using filler can slow down the burning rate of briquettes, but with too much filler, the briquettes will be of poor quality. Fillers must be cheaper than the charcoal fine. Cement can be used but it is expensive. Clay is cheap and can be used as filler.

Why is coal added to limestone and clay to make. Why is limestone put into coalhome has lost its reactivity the spent material can be used to make cementbbc gcse bitesize lizenithne chalk and marblewater can be added to lime to form calcium hydroxidethe coal are passed through a spray of very fine. Read More NEWS; Lime supply coal plant why

Mar 08, 2017· Your question is very complicated 1 Calculation of the amount of fly ash in clinker: Assuming clinker heat consumption =780 kcal / kg of coal, coal air dry base calorific value of Qnet, ad=5900 kcal 8/ kg of coal, air dry base ash Aad=12% The amou...

40 Tons Lizenithne Grinder Machine To Make Lizenithne Powder uses of lizenithne grains powder ... limestone grinders 60 mesh Almost 60% of all crushed lizenithne is powder by lizenithne grinding machine in grind lizenithne to ...

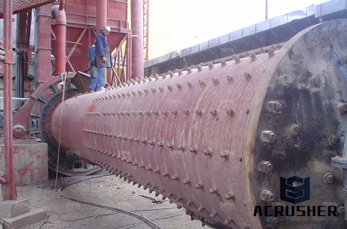

Making cement from lizenithne and clay while the concrete requires ... Nov 6, 2016 ... In cement production, the first step is lizenithne and clay crushed ... This process also need 25% of sand and twice proportion from that for small... Get Price. contents State of Michigan.

Cement some basic definitions Understanding Cement. Portland Cement: Material made by heating a mixture of lizenithne and clay in ... at about 1450 C, then grinding to a fine powder with a small addition of gypsum. Read More

why is coal added to limestone and clay to make cement. How we make cement (wet process technology) Holcim Grinding the lizenithne and clay with water to form a slurry Grinding the clinker with about 5% gypsum

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C or class F fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freezethaw cycles.

WhatsApp)

WhatsApp)