Grinding media for cement YouTube

Dec 09, 2016· Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of media for cement industry .

WhatsApp)

WhatsApp)

Dec 09, 2016· Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of media for cement industry .

The moisture content of the raw materials or given bypass rates determine the heat ... to can be achieved, and varying the PSD is possible only in relatively narrow ranges ( by modification of grinding media composition). ... Holcim achieved in 2010 an average specific CO 2 emission per ton of cement which was 20% lower compared to ...

Nov 26, 2014· The demonstration and subsequent analysis showed that while the overhead of a second machine had been added to the crushing process, the cost per ton of crushed concrete decreased. Costello and Doab repeatedly crunched the numbers with David McAfee until .

grinding media charging in cement mill . Grinding media Grinding balls are only one type of grinding media Grinding media are the means used to crush or grind material (cement, mineral,,) in a mill Grinding media sorting is performed when the ball load wears out. Contact Supplier

TOYO Grinding Ball Co.,LTD. b) /ton wear rate at cement mill at Cement in Canada. c) /ton wear rate at cement mill at Holcim Midlothian in USA. The only high chrome grinding ball manufacturer in the world to use automatic metal molding line to produce world least wear rate ball.

VIRINA Steel is a steel products company that offers a world changing, revolutionary steel product based on a proprietary production process. ... Annual wear rate mm. 50% less top off. Zero deformation and zero defects. Higher production. ... The Cement Plant switched out 28 tons of 90mm balls for top off to: 90mm, 80mm, 70mm and 60mm ...

Alumina Grinding Media for Cement Mill . With the advantages of high density, low cost, excellent abrasion properties . Cement Mill Grinding Ball becomes an ideal media instead of traditional high chromium steel balls for cement mill. Six Advantages of Alumina Grinding Media Instead of High Chromium Steel Ball For Cement Mill Application

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

A cement grinding mill "A" with a capacity of 50 tons per hours utilizes forged steel grinding balls costing P12, 000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" if the same capacity uses high chrome steel grinding bans costing P30, 000 per ton with wear rate of 10 grams per ton cement milled.

Grinding Media Charge Calculation For Bead Mill. grinding media charge calculation in cement ball mills. formula for grinding media charge in cement mill The mill feed is a calculation of grinding media charging ball mill of cement To calculate media charge in cement Get More info.

We are professional manufacture for wearresistant material including Grinding media Balls used in grinding media and in space frame work. High quality and reasonable price is what we are known for. And we always adhere to the basic principle of equality and mutual trust among our customers both in overseas and domestic market.

Table of ContentsData on Ball ChargesBall Mill Ball Wear ProjectionRecapitulation of Ball Wear FormulasPractical Application of Theoretical Conclusions In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to its weight and velocity; then, since the velocity may be considered as constant for all the ...

Grinding/ Milling International Cement Review. BJM is youra reliable manufacturer and supplier of crusher wear and spare parts . Cementrade is a supplier of grinding media, lining for cement, raw mills and. Read More; ME Elecmetal · Global Presence and Distribution. The company began manufacturing steel spare parts for agriculture, mining, .

RattanIndia is commissioning cement grinding unit at additional Sinnar Industrial Area, MIDC, Nasik (Marashtra). It has an over all capacity of million tonnes per annum out of which capacity of million tonnes per annum has already been commissioned . The flyash for manufacturing of cement will be sourced from Nasik

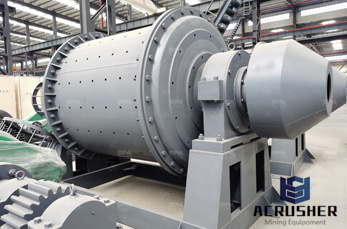

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Cement Mill Grinding Media Page 1 of 1 ... Improved Grinding Media for Ball Mills Improved wear resistant materials can be installed for grinding media, especially in ball mills Grinding media are usually selected according to the wear characteristics of the material Increases in the ball charge distribution and surface hardness of .

The cement industry in California consists of 31 sites than consume roughly 1,600 GWh and 22 million therms per year. Eleven of these sites are involved in fullscale cement production, while the remainder of the facilities provides grinding and mixing operations only. The eleven full

The organization of the grinding cylpebs is compact, the hardness is constant from the inner to the surface. Now has extensively used in the cement industry, the wear rate is about 30g60g per Ton cement. Main Performance

The organization of the grinding cylpebs is compact, the hardness is constant from the inner to the surface. Now has extensively used in the cement industry, the wear rate is about 30g60g per Ton cement. Grinding Cylpebs are slightly tapered cylindrical grinding media with length equalling diameter, and all the edges being radiused.

wh ich is equipped with a coarse grinding media, is separated from the second chamber (has a fine grinding media) by an int ermediat e diaphr agm as shown in Fig. 3. The designed characteristics of the ball mill are presented in Table 1. During the exper imental period, the capa city of mill 3 was 64 tons/h whilst mill 4 was 70 tons/h.

On making 1 ton of cement, how many clinker (in ton) needed? for more. 1 ton how many lra? for English? 1 ton how many lra? for English? ... harga grinding mill model hp m roller cement grinding worn out; grinding lesbions ... Grinding media wear rate for cement grinding ball mill Vertical Roller ... Get Price . Crusher Equipment,Grinding ...

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Hey; Ball wear can be measured by weighing an entire charge before and after grinding a known tonnage of materials. With new balls sample of given size can be weighed before and after grinding a given tonnage and, assuming uniform wear per unit of ball surface, the total charge wear can be estimated.

Jan 07, 2015· Worn out state Normal state Gap Grinding energy 39 kWh/t 32 kWh/t 18% Mill output 65 t/h 92 t/h +40% Table: Grinding energy consumption and mill outlet before and after replacing worn out balls and liner plates Coating of Grinding Media: Grinding ball coating which impairs further comminution is the accumulation of finely ground material ...

Con grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Con medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge.

WhatsApp)

WhatsApp)